Looking for Plumber Parramatta Sydney and wondering what is back pressure in the pipeline? We are here to provide you with all commercial plumbing services that will help you solve your plumbing problem issues as soon as possible.

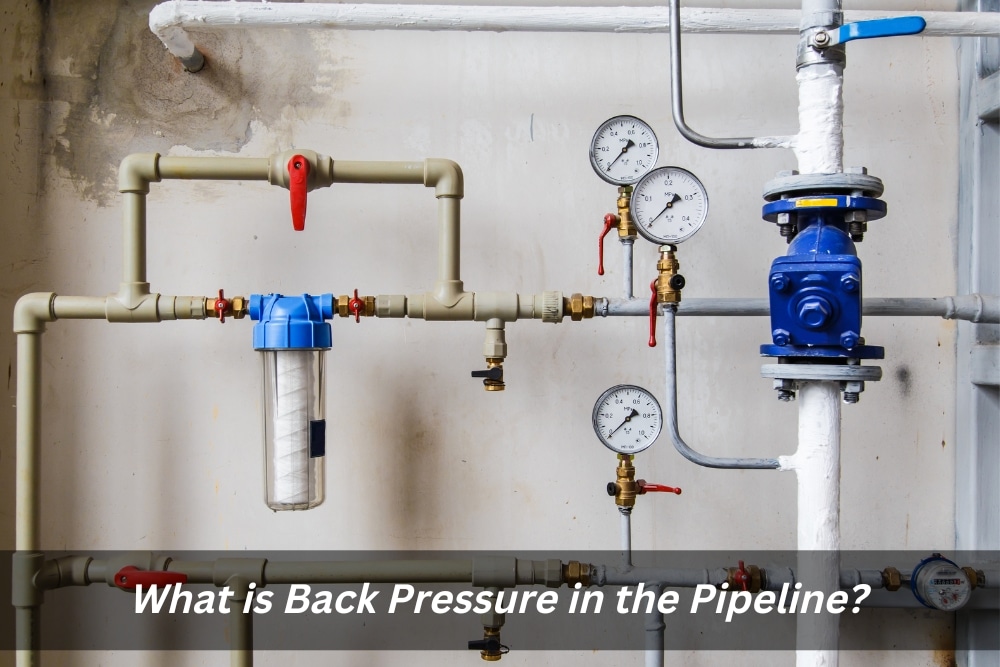

Pipelines are essential parts of our daily lives. They transport oil, gas, water, or other liquids from one place to another. Pipelines come in various sizes and shapes. The size depends on the amount of liquid being transported.

Most pipelines consist of two sections: a section where the liquid flows through the pipe (the inside) and a section where the liquid travels along the outside of the pipe (the exterior). These are called the interior and exterior surfaces respectively.

Back pressure occurs whenever the flow rate exceeds the capacity of the pipeline. Backpressure is created because the liquid has to push against something else. For example, if a pump pushes too much liquid into the pipeline, then the liquid will start pushing back towards the pump.

This causes the pump to work harder than it should, which can damage the pump. To prevent this you should make sure that the blocked sewer pipeline isn’t overloaded by using valves to regulate the flow rate. If your pump starts working hard when there’s not enough liquid flowing through the pipeline, then you need to increase the flow rate. You do this by opening additional valves.

Backpressure is dangerous because if the liquid gets stuck behind the pumps or blocked drains, it could cause them to explode. Another major issue with backpressure is that it can blow out gas fittings and connectors. It also makes cleaning the pipeline difficult as any debris left in the pipeline may get pushed behind the pumps.

The maximum allowable flow rate for piping is typically set at 1 inch per second. This is known as a “design” flow rate. In most cases, the design flow rate is based on the diameter of the pipe. A larger-diameter pipe needs more space available for the liquid to move through it.

Design flow rates are commonly found on pipe charts, but they’re not always accurate. Pipe diameters are often rounded up or down by measuring technicians. The measurements may be off by an inch or even more.

If you have a large diameter pipe and want a higher flow rate than the chart indicates, you’ll need to use different equipment. For instance, a smaller pipe with bigger holes would allow a faster flow rate. However, this means that the pipe won’t handle as much volume of liquid.

To know how much flow rate is acceptable for your specific situation, you should calculate the flow rate required based on the length of the pipe. There are multiple ways to find the flow rate, including a simple calculation. One way is to multiply the diameter of the pipe times the distance between the two ends.

Another reason why you might experience back pressure is due to clogs. Clogs are usually caused by corrosion, sediment buildup, mineral deposits, tree roots, and debris such as small pieces of wood, twigs, metal objects, etc. These obstructions reduce the cross-sectional area of the pipe, causing back pressure.

Backpressure is especially common around areas where the ground is uneven. Areas near creeks and rivers are prime examples of these types of places. When the ground becomes wet, it expands and creates puddles.

As liquid runs across the surface of the ground, it forms rivulets and streams. Hot water systems tend to spread out over a wider area, so it takes longer to travel from one point to another. This creates a gap where the liquid cannot easily pass through the pipe.

How does back pressure increase efficiency?

When the flow rate is less than the design flow rate, the liquid still moves through the pipe, but it doesn’t go very far before encountering resistance. Since the liquid must push against something, it slows down its progress. The slower the liquid travels, the more energy it requires to keep moving forward. This extra energy is wasted, which results in lower overall efficiency.

In contrast, when the flow rate is greater than the design flow rate (or the actual flow rate), the liquid flows through the pipe without encountering any resistance. The liquid doesn’t slow down, so it generates no extra energy.

Instead, it uses the same amount of energy that it did when travelling at the design speed. Therefore, the liquid goes further and covers a lot more territory in a shorter period of time. It’s like getting a boost in power.

Why do we need to consider back pressure?

When designing pipelines, engineers don’t just focus on the total capacity of the pipe. They also think about the flow rate. Back pressure is an important factor because it affects both. The liquid will encounter more resistance if the flow rate is too high.

At the same time, if the flow rate is too low, the liquid won’t get enough momentum to reach the end of the pipe. Engineers can avoid either scenario by ensuring that the flow rate matches the design flow rate.

Is there anything else I should know?

There are other factors that affect the performance of a pipeline. For example, the temperature has a significant impact on the viscosity of the fluid flowing through the pipe. Viscosity refers to the thickness of the liquid.

Different liquids have different levels of viscosity. For instance, water is very thin while honey is thick. In addition, the type of pipe material has an effect.

Hardened steel is stronger and thicker than soft plastic. Also, the size of the pipe affects the flow rate. A larger pipe allows more space for the liquid to move.

What happens if the back pressure exceeds the maximum allowable value?

Pipelines with a higher back pressure than allowed may experience several issues. First, they could be damaged if the pressure gets too high.

Second, they might not operate efficiently or safely. Third, they could even fail completely. All of these things happen because the pipe isn’t designed properly.

The first issue is damage caused by excessive pressure. If the pipe is made of metal, then it could bend or break. Even if the pipe is made of plastic, it could crack.

If this occurs, the pipe loses its integrity and leaks begin to form. These leaks eventually cause major flooding problems so, there needs to fix the problem.

The second issue is unsafe operation. If the pipe is operating outside of its safe range, it could burn up. This means that the liquid inside the pipe would heat up until it reaches a certain level. Once it reaches this threshold, the liquid would start boiling.

Boiling produces steam, which increases the pressure within the pipe. Eventually, the pressure within the pipe would exceed what the pipe was designed to withstand. If this were to occur, the burst pipe would open and the contents would spill out.

Finally, the third issue is the failure of the entire system. If the pipe fails, the liquid would stop moving. As a result, the system wouldn’t work as intended. This could lead to serious safety hazards.

How can I prevent excessive back pressure?

Engineers can use several methods to ensure that the back pressure remains below the maximum limit. The most common method involves using valves. When the valve is closed, the liquid cannot escape from the pipe.

However, when the valve is opened, the liquid flows freely. By adjusting the opening and closing of the valves, engineers can control the flow rate.

Another way to reduce back pressure is to increase the diameter of the pipe. Larger diameters allow the liquid to move faster. Because the liquid moves faster, less force is required to push it along.

In some cases, engineers can install repairs to a pump at the beginning of the pipe relining. The pump creates a vacuum at the end of the pipe so that the liquid doesn’t need to push against any resistance. Licensed plumbers can also add a filter at the end of the line. Filters remove contaminants before they reach the main body of the pipe.

Why would a pipeline require back pressure?

Back pressure exists whenever there’s a restriction somewhere along the pipeline. Engineers put restrictions on pipelines to help maintain their stability. For example, engineers place back pressure valves near the source of the liquid.

Back pressure valves slow down the flow of the liquid so that it won’t overheat. They also keep the liquid from escaping from the line.

Plumbers can also use back-pressure valves to regulate the flow of water. For instance, they can use them to turn off the water supply during heavy rains. Experienced plumbers can also use them to shut off the water supply during times of emergency.

Where should I look if I suspect a back pressure problem?

If you suspect that you have back pressure in the pipeline, then you’ll want to check for signs of a water leak. You might notice a small amount of water dripping from the faucet or shower head. You could also notice water stains on the walls. These are all signs that a leak has occurred.

If you find a leak, you’ll want to locate where the leaking tap is coming from. To do this, you’ll want to examine the area around the pipe. Look for cracks or holes in the wall.

Also, search for damaged furniture or appliances. These items could be responsible for creating a hole in the floor.

Once you’ve located the leak, you’ll want a professional plumber to fix it. A plumber will have a variety of tools to toilet repair the leak. He or she may even use leak detection to pinpoint the exact location of the leak.

If you’re looking for a professional plumbing system company in Sydney, we highly recommended contacting Emergency plumber Parramatta Sydney today! We offer 24/7 emergency service and free quotes.